The first printed 3D heart

On 15 April, a team of researchers from Tel Aviv University presented the heart, which was printed on a 3D bioprinter using the patient's own cells and biological material. And that heart was throbbing! Until now, scientists could print successfully only simple tissues without blood vessels. The report on the results of the work called "3D Printing of Personalized Thick and Perfusable Cardiac Patches and Hearts" is presented in the Advanced Science journal.

Cardiovascular disease is the leading cause of death in industrialized countries. To date, heart transplantation is the only method of treating patients with terminal-stage heart failure. Since the number of heart donors is limited, there is an urgent worldwide need to develop new approaches to the regeneration of the heart affected by a heart attack. Heart tissue engineering opens up an alternative approach to solving the problem by integrating heart cells and 3D biomaterials. The latter serve as temporary scaffolds, mechanically supporting the cells, and thus provide their restructuring into functional tissue. After maturing in vitro (in the laboratory outside of a living organism), the engineered heart patch can be transplanted onto the damaged heart. As integration with the host organ takes place, the biomaterials gradually break down, leaving a fully functioning living section of the heart.

Biocompatibility of "building" materials is crucial to eliminate the risk of implant rejection, which is a risk that jeopardizes the success of treatment. Therefore, the material for 3D printing must be selected carefully. Ideally, it should have biochemical, mechanical and topographical properties similar to those of native cardiac tissues.

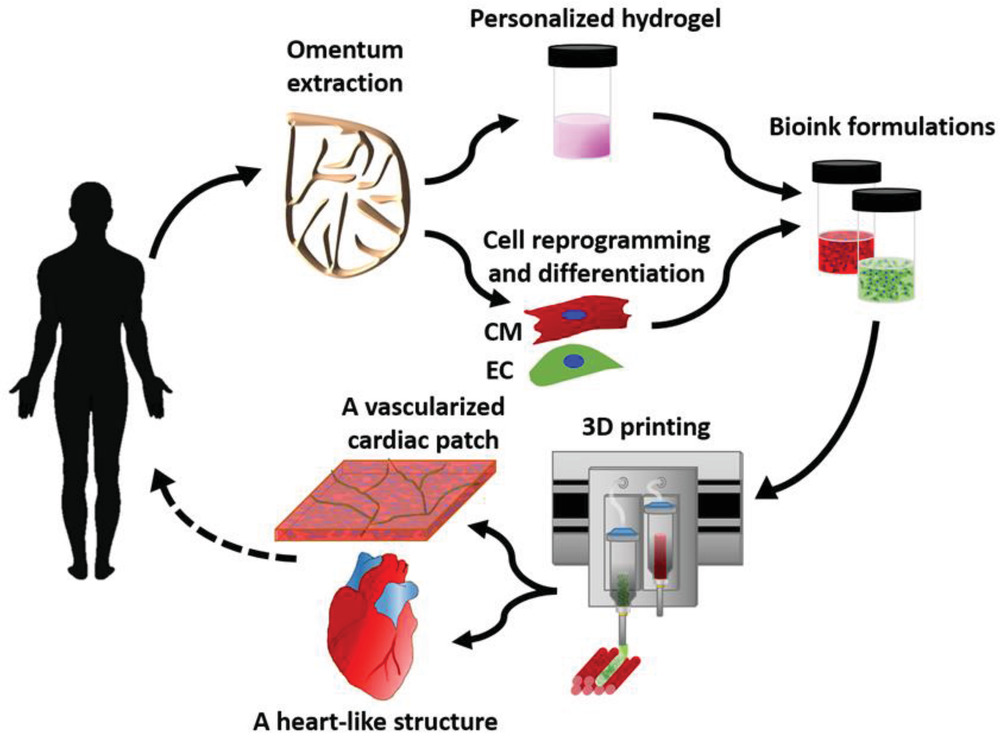

In this study scientists took samples of adipose tissue from donors, isolated individual cells from it, which were reprogrammed into stem cells, and grew heart muscle tissue and epithelial cells. These tissues, as well as personalized hydrogels derived from biomaterial, were used to fill the printer and after that the heart with vessels was assembled out of parts.

"The use of materials of a particular patient, which will not be rejected by the body is the main condition for the successful building of tissues and organs for him," said Tal Dvir, the project leader and Professor of University in Tel-Aviv.

In their report, the scientists from the Dvir team reported on the development and application of advanced methods of 3D printing using personalized hydrogel as biobase. In this strategy, in combination with the patient's own cells, the hydrogel can be used to print thick, vascularized and perfusable cardiac patches that are fully consistent with the patient's immunological, biochemical, and anatomical properties. In addition, it has been shown that personalized hydrogel can be used to print volumetric autonomous cell structures, including whole hearts with their large blood vessels.

It is the first time when researchers managed to successfully design and print a whole heart with cells, blood vessels, ventricles and chambers. The 3D printer used real human tissue to create a living, pulsating heart. Scientists have printed several dozen hearts, but all of them do not exceed 2.5 cm in size. Such organs can be transplanted, for example, to rabbits.

– This heart is made of human cells and patient-specific biological materials. "In our process, these materials serve as bioindicators, substances from sugars and proteins that can be used to 3D-print complex tissue models," Dvir explained.

– The heart is fully compatible with the patient because it is made from the patient's own tissue, and therefore there will be no immunogenic reaction.

The next stage of the project is the maturation of the prototype of the human heart in a special bioreactor. Within a year, such hearts should be experimentally tested on rabbits or rats.

"We hope that in 10 years the best hospitals in the world will have printers for organs, and these procedures will be carried out regularly," said Tal Dvir.

The abstract of the article:

Creating thick vascularized tissues that are completely patient-compatible is still an unsolved problem in cardiac tissue engineering. A simple approach to 3D printing of thick, vascularized and perfusable heart patches that are fully consistent with the immunological, cellular, biochemical and anatomical properties of the patient is described here. To do this, a biopsy of adipose tissue is taken from patients. While cells are reprogrammed to become pluripotent stem cells, and differentiate into cardiomyocytes and endothelial cells, the extracellular matrix is processed into a personalized hydrogel. The two cell types are then individually combined with hydrogels to form bio-ink for a 3D printer to print parenchymal heart tissue and blood vessels. The ability to print functional vascularized patches in accordance with the patient's anatomy is shown. The architecture of blood vessels is further improved by mathematical modeling of oxygen transport. The structure and function of the patches are studied in vitro, and the morphology of heart cells is evaluated after transplantation, revealing elongated cardiomyocytes with massive actinic stratification. Finally, human hearts with natural architecture were printed to prove the concept. These results demonstrate the potential of the approach for designing personalized tissues and organs or for screening drugs in an appropriate anatomical structure and patient-specific biochemical microenvironment.

More on the subject:

In late March, it was reported that Polish scientists have printed the world's first bionic pancreas with blood vessels.